By Allison Thompson

Rosalind Chow and her dog. Image credit: Allison Thompson

Rosalind Chow, an instructor at the University of Minnesota College of Veterinary Medicine, was looking for a better way to teach ultrasound skills.

Veterinary students are taught basic ultrasound skills during their education, including a technique called ultrasound-guided fine needle aspiration. During this procedure, students use the ultrasound to visualize an internal abnormality, such as a nodule, a diseased organ, or a small collection of fluid. Then with the assistance of the ultrasound, they guide a needle into the abnormal site in order to retrieve a sample of fluid or cells that can be examined under a microscope.

As students perform this technique, they place the needle very close to the ultrasound probe. If students hit the ultrasound with the needle, it could damage the probe and lead to expensive repairs. Chow had used makeshift probe covers with mixed success. She was excited to collaborate with Makerspace staff to come up with a solution to protect the ultrasound so students could have more realistic practice with less risk. We asked Chow to tell us more about her experience. Here’s what she had to say.

Q: Tell us a little more about your project. What inspired you to create the ultrasound probe covers?

RC: When performing ultrasound-guided fine needle aspiration, the needle must be inserted within several millimeters of the ultrasound probe. It is not uncommon, particularly with new learners, to accidentally stick the probe with the needle. Our prior attempts to create a probe “shield” were made from the necks of plastic bottles and made handling of the probe very clumsy. Since those shields were not form-fitted, they slipped, moved, and prevented students from being able to properly hold and feel the probe. I wanted to create a form-fitting, removable, and cleanable probe cover that would protect the probe from needle sticks, while also allowing users to handle the probe normally.

Mock demonstration of the ultrasound-guided fine need aspiration technique. Image credit: Allison Thompson

Q: Could you describe the probe covers and tell us a little bit about how they are being used? What have your students said about the experience?

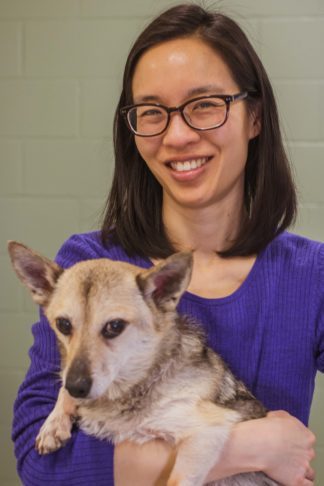

RC: The probe covers are designed to snap on and off of the probe, which is helpful because they can be easily cleaned after use. They can also be left off when not performing fine needle aspiration. Our students are using them in a second-year student emergency ultrasound laboratory. Other veterinary instructors are also using them in other courses, including work with live animals.

Our students used to complain about the old probe covers that we made out of bottles. Since we started to use the 3D printed probe covers, they have not noticed a difference with or without the cover on – which was the goal!

Freshly 3D printed ultrasound probe covers. Image credit: Jonathan Koffel.

Q: How did you connect with the Makerspace at the Bio-Medical Library?

RC: I saw an article on MyU about the availability of 3D printers at the Health Sciences Library. I reached out to Makerspace at the Bio-Medical library with this idea and Jonathan Koffel (Emerging Technology and Innovation Strategist) offered his help. André Nault at the Veterinary Medical Library helped me coordinate a video conference with Jonathan, where I was able to show him the ultrasound probe and provide more specific details about what I was looking to create. Jonathan reached out to Samantha Porter, a digital preservation specialist at the College of Liberal Arts Advanced Imaging Service for Objects and Spaces (AISOS) lab. She used a specialized scanner to create a 3D model of the ultrasound probe. Jonathan subsequently used these scans to create several prototype covers.

Image credit: Allison Thompson

Q: What value did Makerspace staff bring to your project? How did their expertise combine with your own subject matter expertise to make the project both possible and successful?

RC: Jonathan knew that we needed to obtain high-quality 3D scans of the probe and helped to bring Samantha Porter into the project. With those scans, Jonathan brought his knowledge of 3D printing, both in materials and design, to create a probe cover that was thin, form-fitting and lightweight.

Q: What do you see as both the short- and long-term outcomes of introducing 3D printed probe covers to veterinary teaching and learning?

RC: Our goal is to teach students basic ultrasound skills that they can readily use in their professional career. Ultrasound-guided fine needle aspiration is an example of a simple, but important procedure that can provide helpful diagnostic information in certain veterinary patients. The ultrasounds and ultrasound probes were purchased with an educational grant several years ago, so if they became damaged, we did not have a ready source of funds with which to repair them. Using these probe covers has reduced the risk that accidental needle sticks will damage the probe and make it unavailable for future students.

Q: Please share any additional information about your experience working with the Libraries, your work, or the impact of this project.

RC: I’m grateful to the Health Sciences Library team, notably Jonathan Koffel and André Nault, for supporting this project and helping me find a way to make this project come to fruition. Through Jonathan’s contact with Samantha, he was able to help me navigate the different steps of the project. It couldn’t have gone better.

Q: What advice would you offer others who want to get started?

RC: If you have a good idea that involves 3D printing, reach out to your local U of M library. They may be able to put you in touch with people who can help it get off of the ground.